Motorized TV Stand 360° – move your 26-60″ TV

you notice it in motion first: a low, deliberate roll and then the screen easing into a new angle like it belonged to the room all along. The Motorized TV stand, listed as the Mobile Stand 360° Rotating Wheels Frame, sits lower than your usual console, its cold‑rolled steel catching the light in a restrained, utilitarian sheen. Up close the frame feels solid under your hand,a slight texture at the welds and a reassuring give in the casters as you guide it; the whole assembly has a visual weight that quietly anchors the TV without shouting for attention. Small factory marks and the measured whirr of the motor keep the impression practical rather than precious,the kind of object you live with rather than display.

Your first look at the motorized TV stand and how it sits in your room

When you first move the stand into place you notice how it occupies the room without needing to be anchored: it rolls in, you stop it, and the TV settles into a familiar focal point. The unit’s presence is practical rather than decorative — it creates a new sightline and subtly shifts how other furniture reads around it. As you nudge it forward or back a few inches to center the screen, small habits show up: you smooth the cables, click the wheel locks, and step back to check the viewing angle. A few immediate visual cues stand out:

- Footprint: the base takes a readable amount of floor space and defines a small perimeter you’ll avoid stepping across.

- Edge clearance: there’s usually a little gap behind the screen where cables gather and the mechanism is visible from certain angles.

- Movement impression: the motorized shift is noticeable but not startling; you hear a quiet whir and the screen eases into its new position.

Over the first few days the stand becomes part of routine room behavior: you rotate it to catch a different seating group, roll it slightly to clean behind, or tuck it closer to a wall when you need the floor space. That movement exposes practical realities — the back of the screen becomes more visible when angled, the cable bundle wants periodic tidying, and the castors respond differently on rugs versus hardwood so you sometimes make tiny adjustments to stop it from drifting. The table below summarizes common positions you’ll see and the visual result in the room.

| Position | What you notice |

| Centered, facing seating | The screen reads as the room’s focal point; cables mostly hidden from front view. |

| Angled to the side | More of the stand’s frame and cable routing are visible; sightlines change for side seating. |

| Rolled toward wall | It frees floor space but exposes the rear for quick access to ports and plugs. |

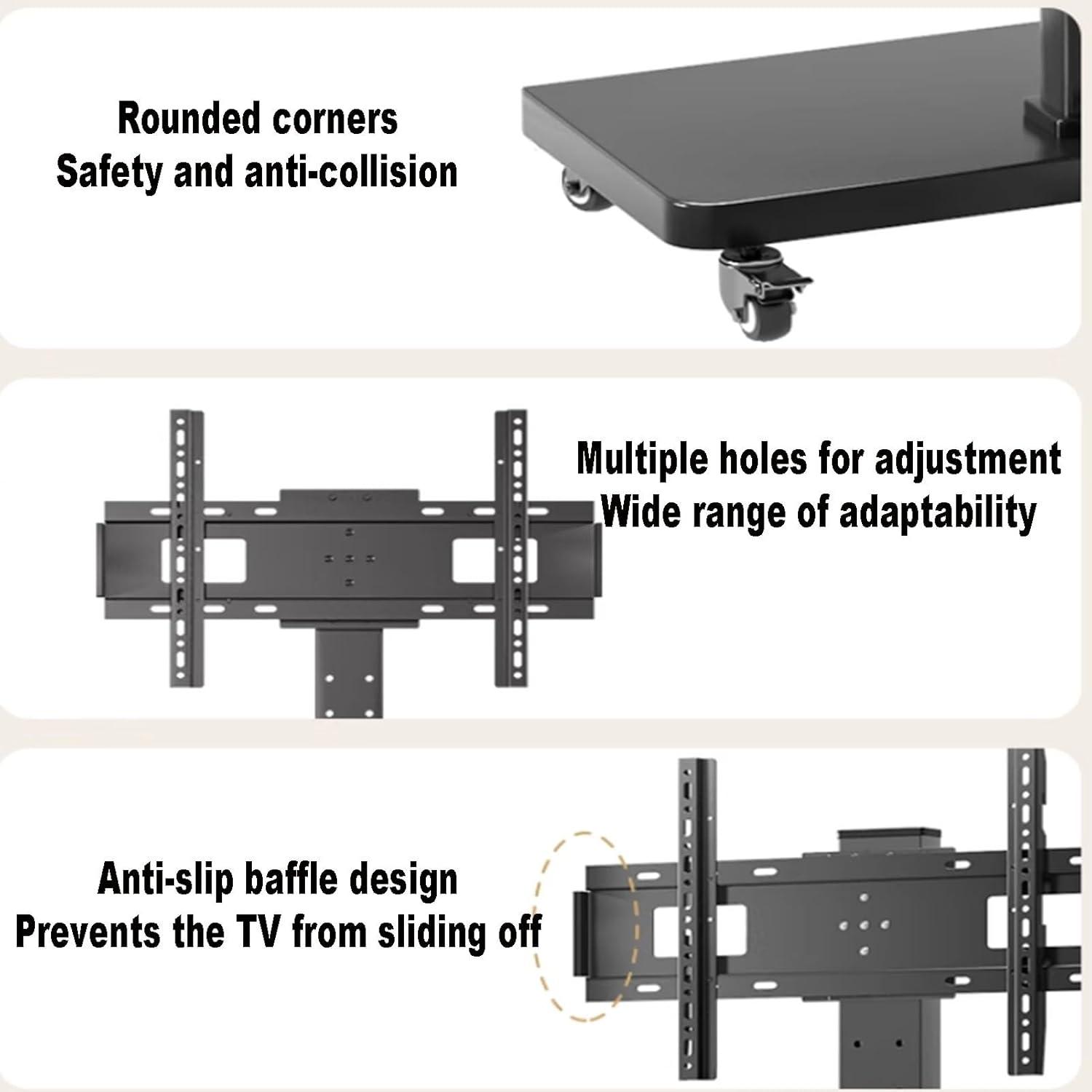

The frame, finishes, and materials you can see and touch around your screen

When you stand in front of the screen the most immediate impressions are visual and tactile at once: the main uprights show a cool, dense metal feel where the cold-rolled steel meets your hand, and the powder-coated surface tends to be matte rather than glossy so fingerprints and smudges are less obvious. Weld seams and joint plates are visible if you crouch down, and the paint around those joins can feel slightly raised compared with the smoother flat sections. Plastic end caps and covers soften exposed corners and take the brunt of contact when you nudge the stand; they have a firmer, hollow sound beneath your fingers. The caster housings and the rubber tread on the wheels give a different texture—slightly tacky under pressure—and small access holes or recessed bolt heads invite the occasional screwdriver or Allen key touch when you make a height or tilt adjustment.

Close-up touches reveal a few repeated materials and finishes that you’ll notice in everyday use:

- Uprights and arms: powder-coated cold-rolled steel, cool and hard to the touch.

- Edge trims and caps: molded plastic with a matte surface that resists scuffs.

- Wheels and feet: rubberized tread over a plastic core, yielding slight give when pressed.

- Fasteners and guides: exposed hex bolts and stamped steel plates with crisp edges.

| Part | Visible finish / material |

|---|---|

| Vertical column | Matte powder coat over cold-rolled steel |

| Cable cover | Snap-on plastic, slightly flexible |

| Casters | Rubber tread with plastic hub |

You may find yourself brushing small dust from crevices or nudging a cap back into place now and then, and those routine touches are where the mix of metal, plastic and rubber becomes most apparent.

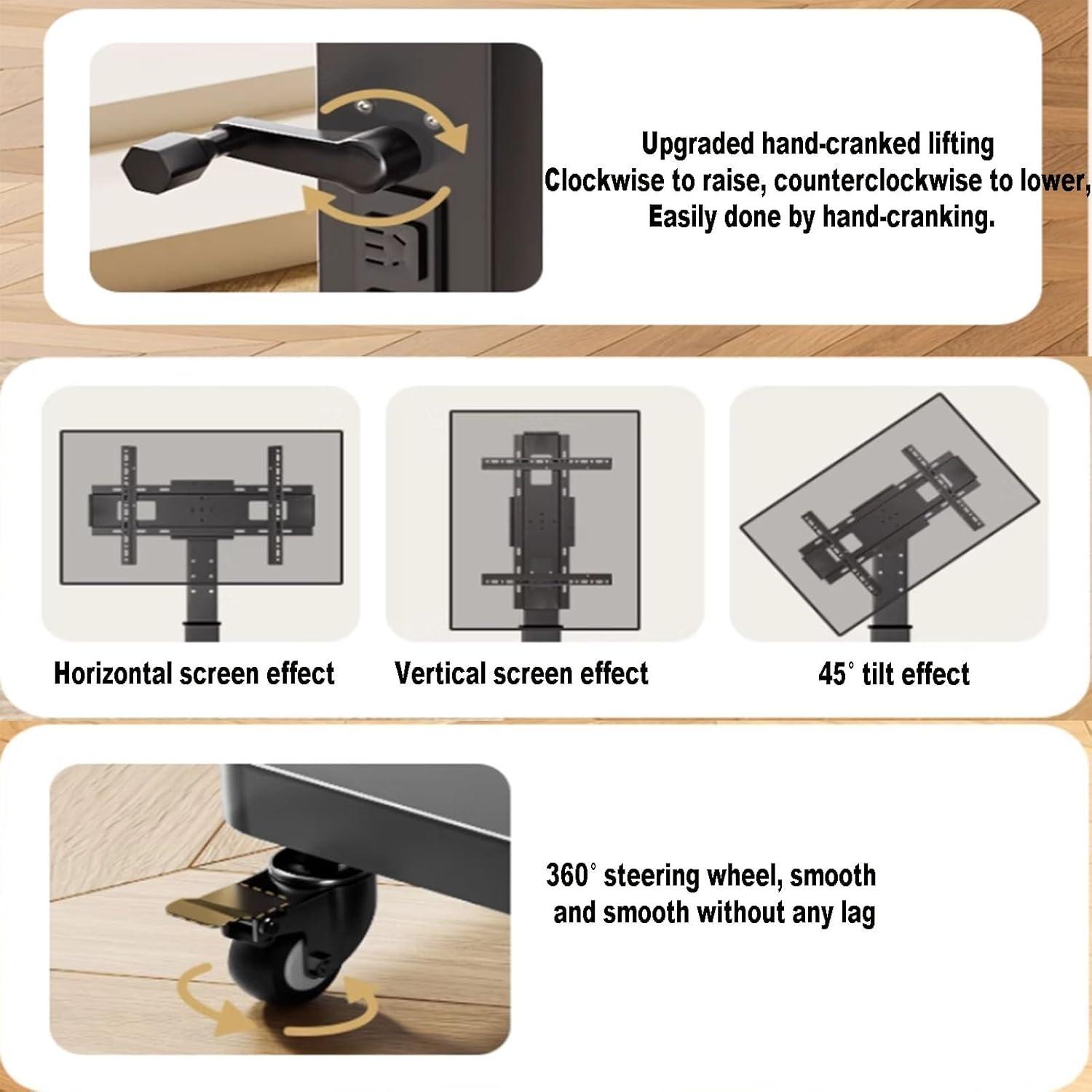

How the full rotation, motor, wheels, and controls behave when you move your TV

The full rotation behaves like a deliberate, motor-driven motion rather than a loose swivel; when you initiate a turn via the control it begins with a soft, momentary surge and then moves at a steady pace until it reaches the commanded angle. If you try to nudge the screen by hand while the unit is powered, there’s a noticeable resistance and the motor gives a small, automatic correction when power is restored—so manual adjustments tend to be fine for tiny tweaks but feel different from an unbraked lazy‑susans. In everyday use the motor produces a low, consistent hum during movement rather than abrupt noises, and the rotation stops cleanly at set points; occasional micro‑adjustments are normal when you’re aligning the picture to a specific seat in the room. Controls respond within a second or so, with the remote and any onboard buttons sending predictable feedback; for safety the mechanism will hesitate or stop if it detects a firm obstruction while turning.

When you move the whole stand across a room, the wheels determine how that motion plays out: on hard floors the casters glide and let you reposition the set with minor steering inputs, while thicker rugs or higher‑nap carpet require more effort and the frame can feel a bit damped. There’s a visible brake/lock action on the wheels that clicks into place and prevents rotation once engaged, and you’ll sometimes re‑center the screen after rolling as the rotation system and rolling casters don’t automatically synchronize. Below is a brief reference of observed interactions between commands, manual handling, and rolling behavior.

- rotation feel: smooth, motor‑paced movement with slight initial surge.

- Motor noise: low hum during travel, quiet at rest.

- Control response: sub‑second response with obstruction sensing and clean stops.

| Action | Observed behavior | Notes |

|---|---|---|

| Rotate via remote | Starts quickly, moves steadily, stops accurately | Short delay under 1s; obstruction sensing active |

| Rotate manually (powered off) | Noticeable resistance; no motor assistance | Best for small angle tweaks, not full rotation |

| Roll stand across floor | glides on hard floors; slower on carpet | Engage wheel locks to prevent unintended swivel |

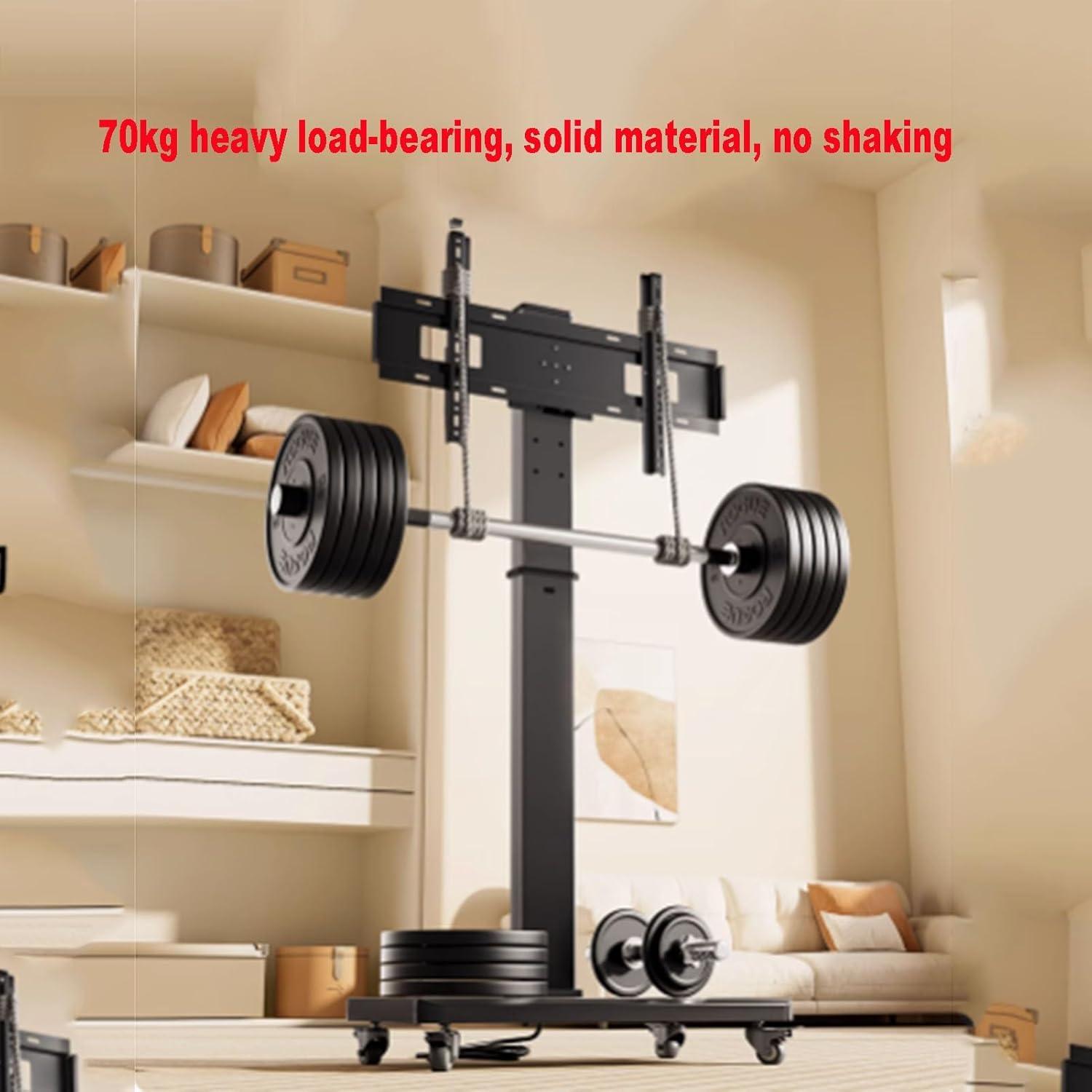

Dimensions, load bearing figures, and the mounting interface that come with your stand

when you check the technical bits that matter during installation, the stand lists a clear set of numbers: a VESA hole spacing that runs from 100×100 up to 400×400 mm, a nominal load-bearing figure of 70 kg, and an indicated fit for displays between 26 and 60 inches. those values are printed alongside the material callout — cold-rolled steel — and they show up again on the instruction sheet,where a gentle caveat notes that measurements were taken manually and might vary slightly. In practice you’ll find the mount plates and column labelled to match those ranges, which makes it straightforward to confirm basic compatibility before you start unboxing hardware.

- VESA range: 100×100 – 400×400 mm

- Load-bearing capacity: 70 kg

- Declared display range: 26–60 inches

| Specification | Recorded value |

|---|---|

| VESA hole spacing | 100×100 – 400×400 mm |

| Load-bearing capacity | 70 kg |

| Compatible screen size | 26–60 inches |

| Primary material | Cold-rolled steel |

The mounting interface feels utilitarian: two vertical plates attach to the screen and then slot onto the main carriage,secured with hex bolts and washers that are supplied in the pack. You’ll loosen a couple of fasteners to slide the plates to the correct VESA holes, then tighten them and make small tilt or level corrections before rolling the stand into place.A shallow channel along the column gives you an obvious place to route cables as you work, and the wheel locks let you immobilize the base once the screen is set.Expect to do a little fiddling — small shifts of the plate or a spacer hear and there — rather than a single, seamless click-in step; minor adjustments are part of the usual mounting routine.

How it maneuvers through your doorways and around furniture during everyday use

When you wheel it from room to room it behaves like a tall piece of furniture on casters rather than a rigid appliance — you angle the base through a doorway,nudge the frame,and let the wheels find the path. The swivel casters track across hardwood and tile with little resistance; on low thresholds or thicker carpets you’ll often give the front a short lift so the wheels clear cleanly. In narrow hallways a short back-and-forth rocking motion is the usual way to reduce the turning radius, and rotating the screen on the mount a few degrees can prevent an arm or edge from catching on a door frame. A few small, repeatable habits tend to appear during use: you pause to reposition after a tight turn, you lock the casters once in place, and you keep an eye on nearby furniture edges while easing past them.

| Situation | Observed behavior / clearance |

|---|---|

| Standard interior doorway (~30″) | Passed with a slight diagonal approach; minimal scraping when angled. |

| Low threshold or thick carpet | Wheels roll but occasional brief lift needed to avoid catching. |

| Tight corner beside sofa or table | Small pivoting motions and minor rotation of the screen prevent contact. |

moving it around chairs and coffee tables tends to be incremental — you roll, stop, tweak the angle, and continue — rather than one continuous sweep. The base needs a little clearance for its pivot arc, so in compact layouts you’ll find yourself habitually choosing routes with a touch more space or angling corners differently to pass through without brushing nearby legs or cushions.

How the stand measures up to your expectations and where practical limits appear

The stand generally behaves like a purposeful piece of equipment rather than an ornamental accent: motorized movement comes across as deliberate and measured, with rotation that rarely jerks but can feel slower when the frame carries a heavier panel. On flat, hard floors the casters facilitate straightforward repositioning and the locking mechanism keeps the frame from drifting, though rolling over thick-pile carpet tends to take more effort and mouse-like nudges are common when fine alignment is needed. Assembly and initial cable routing settle into a routine after the first few adjustments, and occasional minor tightening of fasteners emerges as a normal part of living with the unit rather than an unexpected fault.

Practical limits become most apparent in everyday contexts where weight distribution, room layout, or power access matter: prolonged or frequent rolling with a fully loaded screen highlights small amounts of lateral play and the motor will tend to slow slightly under sustained heavier loads. Observations include:

- Mobility: smooth on hard surfaces, reduced ease on deep pile carpet

- Rotation under load: steady but slower when the frame carries near-maximum weight

- Placement constraints: base footprint and cable length can restrict how close the unit sits to walls or furniture

| Condition | observed Behavior |

|---|---|

| Hard floor | Easy to roll and lock; minimal wobble |

| Thick carpet | Requires more force; casters can bind slightly |

| Heavy load | Rotation speed reduces; small lateral play noted |

Full specifications and configuration details are available on the product listing: View full specifications

What to expect during setup, adjustments, and routine upkeep in your home

When you unbox and put the pieces together at home, expect the process to feel like a small furniture project rather than an electronics hookup. Parts typically arrive laid out in foam or boxes, and assembling the upright, mounting plate, and caster base will probably take most of the time; you’ll find yourself pausing to align holes, thread bolts, and check that the bracket sits square. Attaching the screen and testing the motorized rotation usually requires a moment of coordination — someone steadying the display while another tightens fasteners — and plugging in the power lead to verify the rotation range and any remote or control buttons. Small practical things crop up: rerouting cables so they don’t catch when the unit turns, choosing a place with enough clearance for a full sweep, and locking the wheels so the stand stays put when you want it to.

- Tools you might need: a Phillips screwdriver, an adjustable wrench, and a tape measure for positioning.

After setup, routine upkeep settles into a light, occasional rhythm. You’ll likely check fasteners after the first few days and then every month or two; casters benefit from a quick wipe to stop dust building up in the wheel housings,and any exposed swivel joints can be given a drop of lubricant if they begin to make noise or feel stiff. Cable management becomes an ongoing habit — tucking, retying, or replacing ties as devices change — and keeping the area around the base clear prevents accidental nudges or scuffs to the floor. Below is a simple reference for common tasks and how often they tend to come up in normal use:

| Task | Typical frequency | Typical time |

|---|---|---|

| Initial assembly and power-up | Once,at setup | 30–60 minutes |

| Fastener and bracket check | After first week,then monthly | 5–15 minutes |

| Wheel and track cleaning | Monthly or when movement feels uneven | 5–10 minutes |

| Cable tidy and power check | Whenever devices change; quick weekly glance | 5–10 minutes |

How the Set Settles Into the Room

After a few weeks you notice the Motorized TV Stand,Mobile Stand,LCD TV 360 Degree Rotating Wheels Frame Floor Stand folding into the background of daily living rather than demanding attention. In daily routines it moves with a small,predictable economy as the room is used,nudging where people sit and how arms rest on the sofa in moments of comfort behavior. The finish gathers the faint, everyday marks of use and the occasional soft scuff from passing feet, and those marks begin to read like familiar handwriting.Over time it simply stays and blends into everyday rhythms.